In the previous article of this series, we discussed the power of first principles thinking, which involves breaking down complex problems into their fundamental components to gain a deeper understanding and identify new solutions. In this article, we will explore how first principles thinking can be applied to the world of 3D printing to design more innovative and sustainable products.

Designing a 3D Printed Part

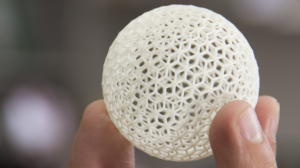

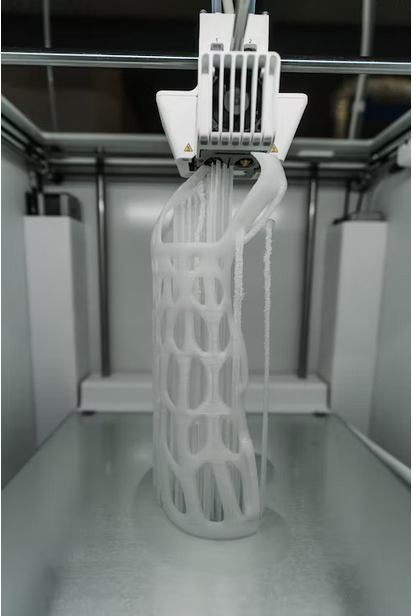

Let’s consider an example of designing a new 3D printed part for a manufacturing process. Rather than relying on existing designs or solutions, first principles thinking can help break down the problem into its essential components. This involves asking questions such as what is the part’s purpose, what materials are required, and how can the part be optimised for its function? By answering these questions, we can build a new design from scratch, leading to more efficient and innovative designs, as well as identifying cost savings and material efficiency opportunities.

Selecting Sustainable Materials for 3D Printing Applications

When it comes to selecting sustainable materials for 3D printing applications, first principles thinking can also be applied to ensure that the chosen materials meet specific requirements. For example, natural polymers are biopolymers found in plants, animals, and microorganisms, which have unique properties such as biodegradability, biocompatibility, and sustainability, making them attractive materials for 3D printing applications.

To apply first principles thinking to the selection of natural polymers for 3D printing, we must break down the problem into its fundamental components. First, what is the intended application of the 3D printed part? Is it for medical, industrial, or consumer purposes? Secondly, what properties and characteristics are required for the material to perform optimally in that specific application? For instance, biocompatibility may be crucial for medical applications, while strength and durability may be essential for industrial purposes.

By answering these questions, we can evaluate various biopolymers and choose the one that best meets our requirements. Here are some examples of biopolymers and their potential applications:

- Polylactic acid (PLA)

PLA is a biopolymer derived from corn starch or sugarcane, and it has become a popular choice for 3D printing applications due to its biodegradability, low toxicity, and ease of use. PLA is often used for consumer products such as phone cases, toys, and kitchenware.

- Cellulose

Cellulose is a biopolymer derived from plant cell walls, and it has excellent mechanical properties such as strength, stiffness, and toughness. Cellulose has been used for various applications such as packaging, textiles, and biomedical devices.

In general, the versatility of cellulose as a renewable feedstock combined with the freedom of design provided by additive manufacturing is a perfect match for the development of sustainable solutions for advanced applications.

- Hemicellulose

Hemicellulose refers to a group of complex carbohydrates that are found in plant cell walls. It is a polysaccharide that plays a structural role in the cell wall, along with cellulose and lignin. Hemicellulose is often described as a “glue” that holds the cellulose fibers together in the cell wall. Unlike cellulose, hemicellulose is more easily broken down by enzymes, and can be used as a source of energy or for the production of biofuels.

- Lignin

Lignin is a complex organic polymer that is found in the cell walls of many plants, especially woody plants. It is a major component of the secondary cell walls, which provide structural support to the plant. Lignin is composed of aromatic units and is highly resistant to degradation by enzymes. It plays an important role in the mechanical strength of the cell wall, as well as in water transport and the defence against pathogens. Lignin also provides resistance to decay and contributes to the characteristic hardness and durability of wood.

- Chitosan

Chitosan is a biopolymer derived from crustacean shells, and it has unique properties such as biocompatibility and antibacterial activity. Chitosan has been used for medical applications such as wound dressings, drug delivery systems, and tissue engineering scaffolds.

- Polyhydroxyalkanoates (PHA)

PHA is a biopolymer produced by bacteria, and it has properties such as biodegradability and biocompatibility. PHA has been used for medical applications such as implants, drug delivery systems, and tissue engineering scaffolds.

All of these biopolymers have been already 3D printed, often with astonishing results. For example, as described in this article, chitosan was used to create a 3d printed air turbine and cellulose was used to create a material that is stronger than steel.

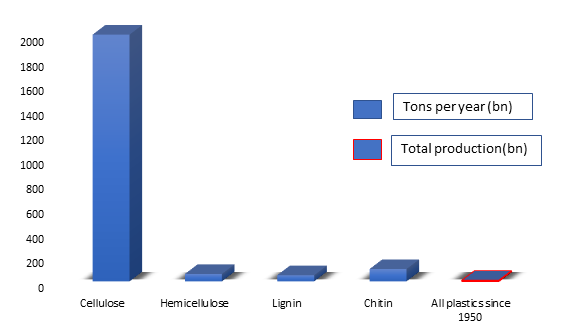

Of course, challenges for 3D printing these materials, like material properties, printing parameters and material cost exist, but further research and collaboration will help to overcome these hurdles. As shown in the above graphic, the abundance of materials should accelerate their deployment.

Conclusion

By applying first principles thinking to the selection of natural polymers for 3D printing, we can identify the best materials for specific applications, leading to more innovative and efficient designs. Additionally, the use of natural polymers in 3D printing can offer environmental benefits due to their biodegradability and sustainability.