Remember Arris? The tech company behind Additive Molding™, a high-speed manufacturing process that aligns continuous carbon fibers and enables the integration of electronic components and multifunctional materials into a single topologically optimized part or component.

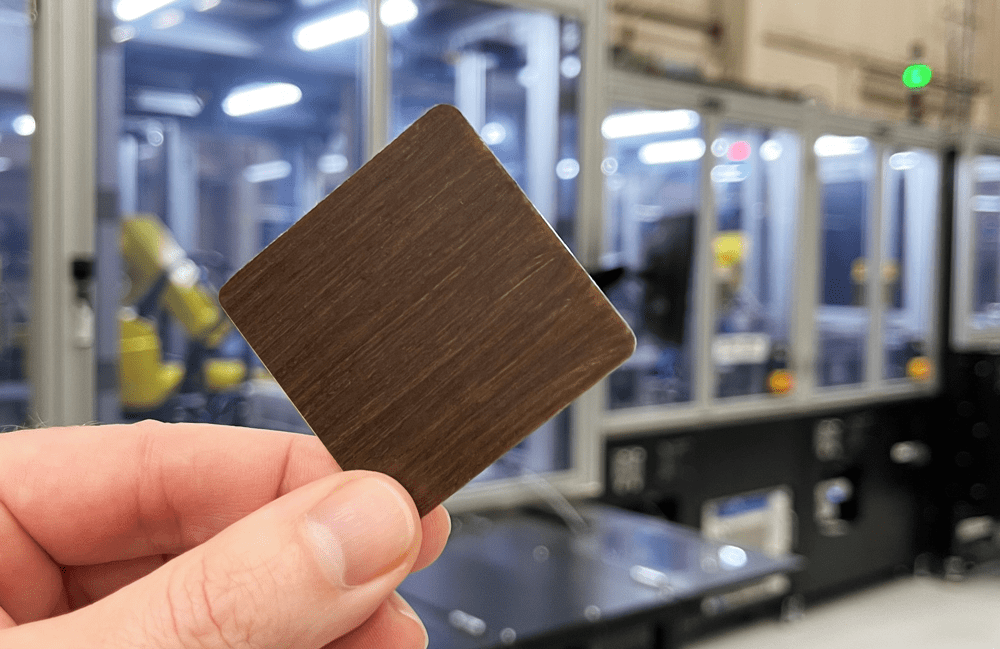

The R&D team has developed natural-fiber composites with high-performance capabilities to complement its already available bio-nylon resin material being used with carbon and glass fiber.

The announcement follows another milestone the company recently hit: the expansion of its Additive Molding production capacity to 1M+ parts on the heels of a partnership signed with a contract manufacturer in Malaysia.

As far as the fiber material solution is concerned, the company explained that since flax fiber is <5% of the CO2e footprint compared to carbon fiber, these advanced composites have a massive impact on further reducing CO2 emissions. (Read More)