There are many misconceptions and myths when it comes to Bioplastics. One example for such a misconception is that bioplastics are considered to be always compostable and can’t be used for engineering applications. However this is not true. Let us have a closer look and see what bioplastics are.

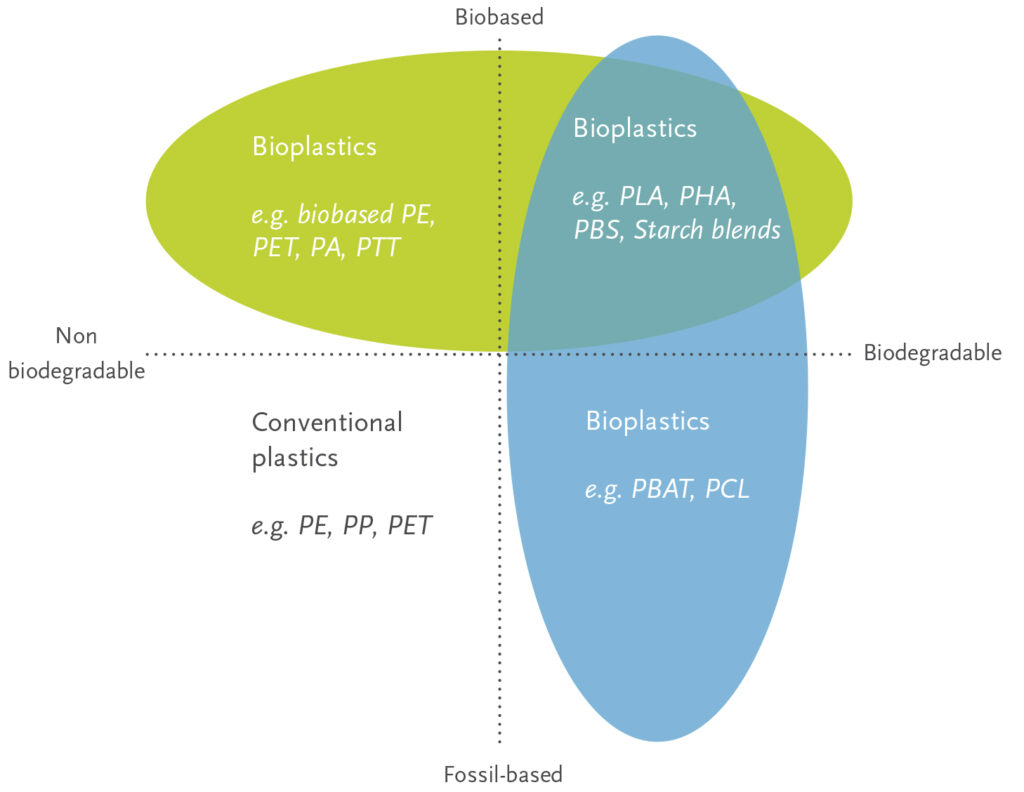

According to European Bioplastics, a plastic material is defined as a bioplastic if it is either biobased, biodegradable, or both. That means bioplastics are not just one single material but consist of a whole family of materials with various properties and applications.

Biobased: The term ‘biobased’ means that the material or product is (partly) derived from biomass (plants). Biomass used for bioplastics stems from e.g. corn, sugarcane, or cellulose.

Biodegradable: Biodegradation is a chemical process during which microorganisms that are available in the environment convert materials into natural substances such as water, carbon dioxide, and compost (artificial additives are not needed). The process of biodegradation depends on the surrounding environmental conditions (e.g. location or temperature), on the material and on the application.

Biobased does not equal biodegradable

The property of biodegradation does not depend on the resource basis of a material but is rather linked to its chemical structure. In other words, 100 percent biobased plastics may be non-biodegradable, and 100 percent fossil based plastics can biodegrade, as you can see in the following graphic.

There is nothing that bioplastics can‘t do: Today, there is a bioplastic alternative for almost every conventional plastic material and corresponding application.

An interesting fact is that already today there is a bioplastic alternative for almost every conventional plastic material and corresponding application. This means that bioplastics have the same characteristics as conventional plastics but can offer additional advantages, such as a reduced carbon footprint or additional waste management options like composting. On top of that they are often conventionally recyclable within existing waste streams.

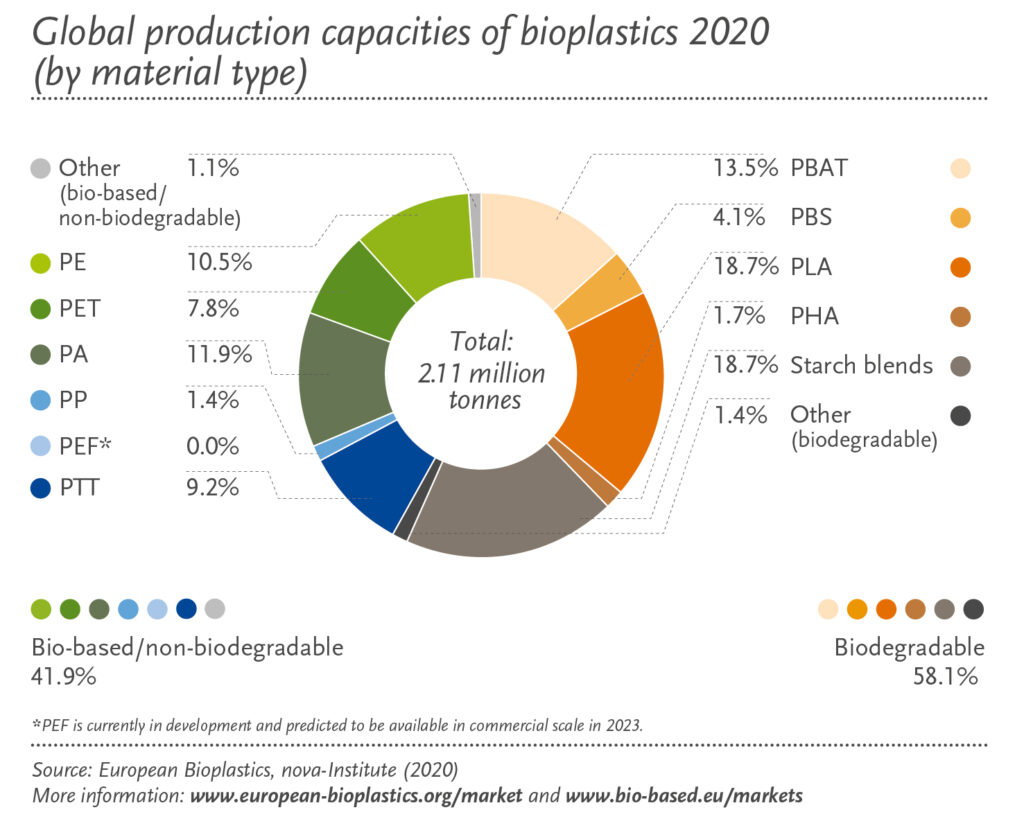

In the following graphic you see the global production capacities of bioplastics in 2020 and the share of biodegradable and non-biodegradable plastics.

In the last years the amount of bioplastics, and in particular the biodegradable plastics, have increase constantly. However, bioplastics still have a long way to go. Currently bioplastics represent only about 1 % of the about 359 million tonnes of plastics produced annually.

But the biolpastic market is expected to grow extensively in the upcoming years. Besides increasing custumer awareness and demand, there are many other market drivers for this growth: One of them is policy engagement, for example the EU just agreed on a plastic tax for all non-recyclable products – this is just one of their measures towards a circular economy. Another one is Corporate Vision: Lego announced that by 2030, it will produce all products from renewable plastics. And scientific breakthroughs make bioplastics competitive not only in price and sustainability, but also in material properties. For example, recently a bioplastic has been developed that can break down in the natural environment shortly after entering the sea.

Its important to realize that the plastic problem won’t be solved by only focussing on recycling and avoiding waste. In fact the most impactful aspect of the circular economy concept is redesigning products and industries from the start to be nontoxic and regenerative, using as much renewable energy and biomass as possible along with safe chemicals and materials. Creating materials from substances that nature understands and can process is an important step towards a more sustainable future.