The automotive industry is the third-largest consumer of polymer materials after the packaging and construction industries. By using engineered plastics with recycled content, automotive companies around the world are becoming less dependent on the consumption of finite resources.

In response to that demand, LANXESS, a leading global supplier of specialty chemicals and polymer materials based in Cologne, Germany, working in close collaboration with leaders in the automotive industry, has developed a range of recycled glass-fiber polyamides suitable for manufacturing of automotive components.

New Technological Developments for More Efficient Manufacturing

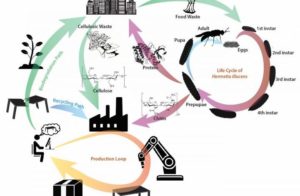

With the growing concerns about climate change, environmental degradation, and rising prices of raw materials, sustainability has become a strategic priority for automotive companies. Through engineering and innovation, the companies in the sector continue to develop new technologies to combat these problems.

Additive manufacturing technology enables more material-efficient component designs along with the utilization of advanced 3D printing materials that are highly-reusable and lower the environmental impact of the final product. (Read more)