In 2023, global events coupled with the cost of living crisis have motivated manufacturers across a range of industries to re-think their centralised production models. We’ve seen more companies integrate technologies like additive manufacturing (AM) into their factory floor operations to work alongside traditional processes, enabling more immediate and cost-effective manufacturing on-demand – helping to meet the challenges head on.

Advances in technology are helping to drive this shift away from short-term solutions-led thinking toward a more strategic approach – using AM for the sustainable production of certified end-use parts, which we’ll see more of in the year ahead.

This article explores trends in manufacturing practices, along with Markforged’s Central European manager Gesa Schnieder’s predictions for the role of AM in 2024.

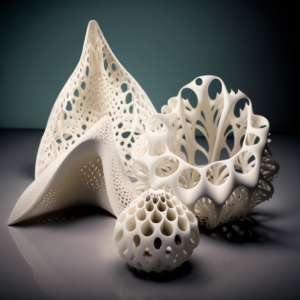

The continuing trend of personalised and on-demand manufacturing

On-shore production and localised manufacturing practices are already providing businesses with greater flexibility, responsiveness, and resilience in the production process, which I believe is set to continue in the coming year.

I predict we will see more designers, engineers and manufacturers across a variety of industries adopting AM to design, test, create and customise the parts, tools and products they need, when and where they need them.

This AM-fuelled drive toward on-demand manufacturing will also help businesses to reduce their transportation and shipping costs, environmental impact, and product lead time, increasing efficiency.

Smart(er) AM

Additive technology is getting smarter. This is due in large part to advances in connected AM platforms that allow machines to collect – and learn from – information with each build. In essence, AI is helping to solve hardware problems with a software solution, creating new opportunities and challenges for AM.

In the year ahead, we will see further integration of data-driven technologies such as sensors, feedback, analytics, artificial intelligence, and the Internet of Things (IoT) continuing to enhance the quality, reliability, and efficiency of the AM process and products.

These data-empowered, Smart AM platforms will add another layer of insurance against supply chain challenges, untimely holdups and failures, helping to perfect designs that allow manufacturers to get the best performance and business returns from every part they print.

Faster printing speeds

Smarter AM also means faster AM. In-built calibration and inspection technologies not only optimise part design and accuracy, but help to speed up the 3D printing process. In addition, increased material capacities and automated material changeover capabilities found in the latest machines like Markforged’s FX10 reduce human intervention and bottlenecks, keeping things running smoothly.

Faster, more accurate prints reduce the time and cost of AM and increase its ROI, making it even more competitive than traditional manufacturing methods. This acceleration also helps new adopters of the technology to learn, test and iterate through faster prototyping, enhancing the innovation and learning potential of AM.

Overcoming challenges, together

With advancements come new challenges, and two which I believe will have an impact on the adoption rate of AM in the year ahead are regulatory issues and tighter budgets.

Collaboration is essential to help address and overcome these obstacles.

While standards bodies like ASTM have developed a range of AM-specific global standards, there is still work to be done. A lack of clear and consistent guidelines, certifications, and quality assurance can pose risks and barriers to widespread adoption of the technology in industries like aerospace. I’m hoping we’ll see all parties sit around tables in the coming year to address these issues and challenges and work together to establish workable standards.

We will no doubt see more restricted budgets across industries in the new year, making it even more essential for any technology to prove ROI. AM providers and their customers can help to advance adoption rates by highlighting the benefits at board level by documenting their successes, sharing proof of concept wins and developing case studies illustrating increased efficiencies and innovation.

Sustainability and ESG

With the global temperature in 2024 set to be the warmest year on record, it will be harder for governments and business to ignore the growing social, and governance (ESG) agenda. While these are complex issues, especially when it comes to manufacturing industries, I believe investors and consumers alike will continue to encourage the development of a circular economy and the reduction of carbon emissions. AM’s role in local and on-demand manufacturing can help to reduce the monetary and environmental costs of waste, energy consumption, and shipping, but there is more to be done.

The industry is already asking questions and exploring issues like: how plastic from processes like 3D printing can be reused, how production waste can be recycled and how we can develop strong, robust filament from recycled materials. I think we will see a move in the AM community toward research and advances in more sustainable materials and processes not just in 2024, but in the years ahead.

As it continues to become smarter, faster, more accurate, efficient, and – undoubtedly – more sustainable, AM will become a more integral part of production lines and manufacturing processes. I believe that in 2024, we will see more additive technology at work on factory floors around the world.