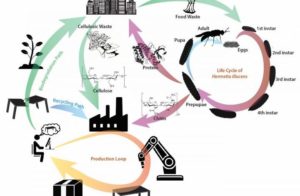

Relativity Space has announced a strategic alliance with 6K, a developer of microwave plasma technology for powder production, to 3D print rocket components made from sustainable materials. The partnership will establish a closed loop supply chain through which scrap materials produced by Relativity will be transformed into premium AM powders by 6K and redeployed to Relativity for production. The companies will also work together to develop new materials for rocket manufacturing and space applications.

“Relativity is completely reimagining the aerospace supply chain, by creating an autonomous robotic factory that can additively manufacture a rocket in 60 days,” said Tim Ellis, CEO of Relativity. “This partnering with 6K will add another important element to our very unique approach: the ability to reuse materials. We are looking forward to working with 6K to add this sustainability to our supply chain, while ensuring closed loop traceability all the way through.”

6K (formerly Amastan) has brought to market a unique and proprietary technology, UniMelt, that is capable of transforming scraps of metal into premium AM-grade powders. Last week, the company announced that it had commissioned the first two commercial UniMelt systems for the production of metal powders – the systems are reportedly capable of producing 100 tons of powder per year.

By leveraging 6K’s cyclical powder production technology, Relativity hopes to improve its own sustainability practices by effectively reusing metal waste to produce 3D printed parts. Relativity, which moved into a larger facility in February 2020, utilizes large-scale metal 3D printing to produce its Terran 1 rocket.Read more

Like!! Really appreciate you sharing this blog post.Really thank you! Keep writing.

I learn something new and challenging on blogs I stumbleupon everyday.

A big thank you for your article.