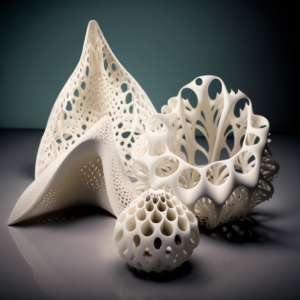

In the first part of the Circular Economy model series it was explained how nature is using simple materials and puts them skillfully together, so that quality materials and objects result that are easy to recycle. Above all nature achieves this through design and its simple choice of materials.

So far we humans were limited when it comes to design. We defined how an object should look like and created the mould or the end product for it with limited flexibility to changes. We are used to these products as we are using them for such a long time, neglecting that they are often just good enough. An example is the shoes you are wearing: You can get them in your size but often they do not perfectly fit to your feet. You are wearing them maybe for a year and throw them away. Much better would be a shoe that perfectly fits to your feet and makes you feel comfortable.

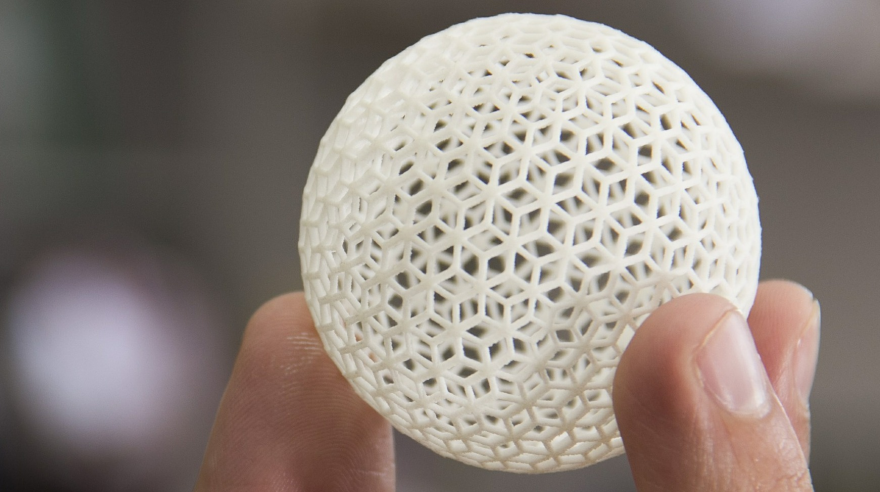

With 3d printing and new design software we have the possibility to create these products. The geometric flexibility that comes with this technology opens the door to an entirely new class of design that uses artificial intelligence and takes inspiration from nature.

Using new generative design tools, engineers outline where a part should exist, what forces are acting upon it and delineate areas to avoid. The rest is up to a computer. Instead of defining that the object should have a certain shape, the computer finds through thousands up to millions of iterations the perfect model. This is how nature has done it over millions and billions of years, just in a more compressed way. With increasing computer power and new parametric design software we are able to create complex but very smart objects, like very light mechanical part or personalized shoes (Source: 3dPrint.com and adidas).

The end results are fully optimized parts as much as 50 % lighter than conventional designs, without sacrificing performance.

By making such parts possible, 3D printing uses fewer raw materials. It can be used to manufacture parts for everything from cars to airplanes, resulting in lower carbon emissions.

Choice of materials is key for achieving Circular Products

Another important pillar to achieve products that can be imbedded into the circular system is the choice of materials.

The possibilities for new materials in 3D Printing are expanding and they bring new opportunities with them, but its important to keep in mind that the problem of our current system and the low recycling rate can be mainly referred back to our wide usage of a big number of complex materials. Humans already are using around 350 polymers and that number is still growing. With better technology and new possibilities in generative design we should rather change to biomimetic thinking on the value of selective and simplistic material selection.

Unlike ever before, humans can create new material functionalities just by design. Yet, unless these smart materials are designed within a smart system, we risk that a lot of these valuable materials will be wasted.

With great power, comes great responsibility. That is why 3d Printing must be directed by circular system thinking, otherwise we are going the risk of speeding up the linear economy by bringing in higher amounts of mixed materials that are harder to recycle and more difficult to keep in the loop. Whereas with the principles of the circular system, 3d printing can be the enabler of a new manufacturing system that is sustainable and generative by design.

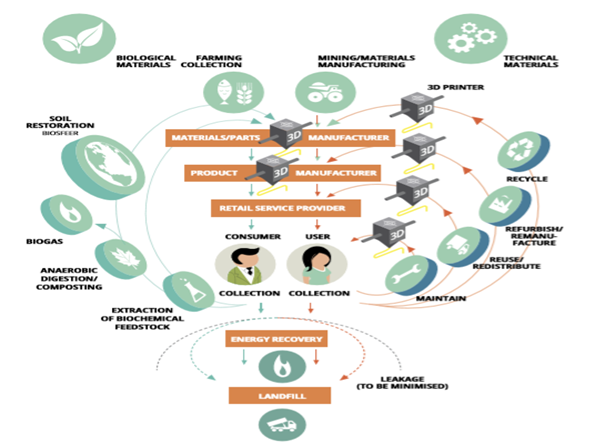

As you can see in the graphic above (Source: Van Wijk, 2015 ) 3d Printing can contribute also in other parts of the circular economy system: especially in maintenance, reuse, remanufacturing and recycling of products and goods.

In order to reach its full potential, 3d Printing must be supported by other disruptive technologies like AI, Robotics, Blockchain, etc. The circular system represents a systemic shift that will affect almost all areas of our economy and the interplay of industries and technologies are key to achieve its full potential.

As 3d Printing stands on the edge of evolving from prototyping to manufacturing, how we lay the foundations for this technology will be important in ensuring that it is an enabler for the transition to the circular economy.

At the same time, the Circular Economy is a golden opportunity, not only under financial aspects but also in terms of creating products that are better for our health, environment and society. We shouldn’t let it go to waste.

Pingback: Biological polymers as a catalyst for the transition to circular manufacturing models (Part 2) – Circular 3d

Like!! Great article post.Really thank you! Really Cool.

Thanks so much for the blog post.

These are actually great ideas in concerning blogging.

I always spent my half an hour to read this web site’s articles or reviews daily along with a mug of coffee.

I love looking through a post that can make people think. Also, many thanks for permitting me to comment!