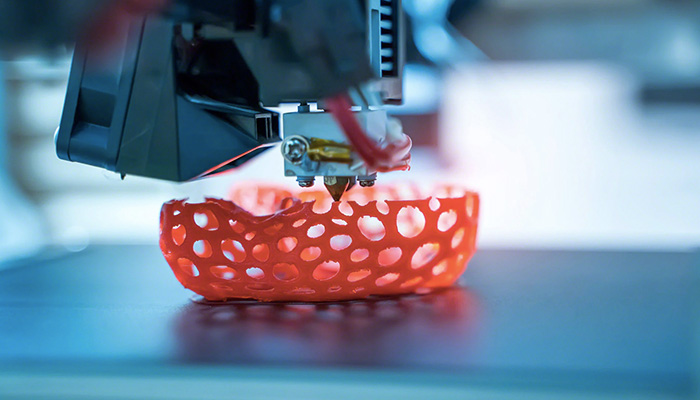

3D printing and digital manufacturing specialist Sculpteo has released its 8th edition of its report, The State of 3D Printing: 2022. Like its seven predecessors, this document is an annual international study that provides an overview of the additive manufacturing industry. Among other things, it allows manufacturers to discover new trends and improve their business strategies. This year, the tone notably was focused on sustainability. Indeed, for the respondents to the study, who are mostly executives, engineers or designers, it seems that 3D printing improves the environmental impact of their activities.

According to the report, 41% of manufacturers believe additive manufacturing helps companies meet their sustainability goals. Continuing with this, 61% of manufacturers believe that this technology allows them to produce the right amount of material for the right need. This advantage avoids the need for a multitude of resources. In traditional techniques, it is necessary to use several materials, which is inadequate for the desired sustainability process. That’s why 3D printing is making a difference. It helps manufacturers maintain a more sustainable policy because they get the exact amount of material needed to make a product.

Unleashing the potential of 3D printing and its reliability

Respondents see materials reliability and sustainability as priority goals. 61 percent of respondents say that on-demand manufacturing is the most reliable and sustainable benefit delivered by 3D printing. 47 percent of users say that 3D printing reduces the need to use multiple resources, because some designs are impossible to achieve using traditional techniques.

According to the results set out in this report, 59 percent of users want to be able to use more sustainable materials. This demand is being driven by the increasing number of bio-based materials that have been introduced in recent years.

According to users, the three aspects of 3D printing reliability and sustainability that most need to be improved are: the availability of more options for recycling printed objects, the development of more sustainable materials, and greater progress in the reuse of powder using technologies like SLS. (Get the Report)